12 Fibers Custom Indoor/Outdoor Single mode PreTerminated Assembly

Reduce installation time with Pre-Terminated Fiber Patch Cables and the controlled factory processes with pre-termination results in superior performance. Consistent, high quality connector end-face geometry results in lower insertion loss and better end-to-end attenuation in the system. The “Pulling Eye” structure plays a critical role in the cable assembly connection. It allows strain relieved and provides excellent protection to connectors. These pre-engineered, factory-terminated and tested trunk cables connect central patch locations to zones or “pods”.

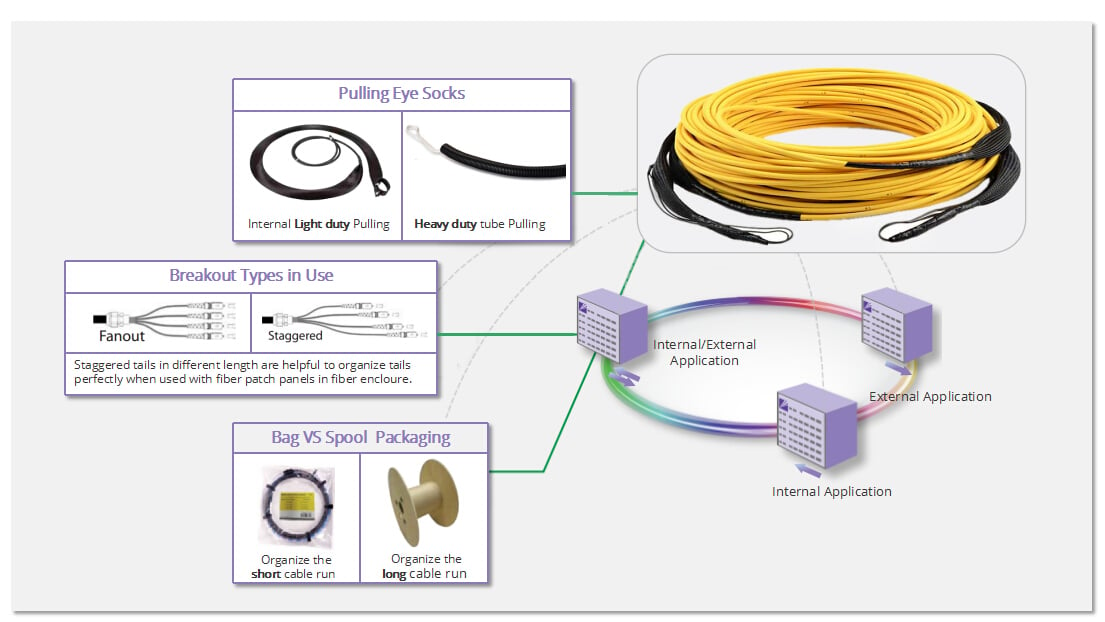

“Pulling Eye” and “Packaging Details” of Pre-terminated Cable Assembly

A pulling eye is recommended in this pre-terminated cable assembly. With this useful structure, hassle-free installation and erro-free performance will be no problem. In some cases, you may need to order the cable with two pulling eyes to pull from an intermediate point rather than from point to point. Besides, we offer excellent packaging methods, such as wooden spool, plastic spool or box according to the cable length, which are easy to move and organize the cable.

Key Features

|

Factory terminated and tested2.0mm default, 0.9mm 3.0mm of breakout OD can be customizedPVC jacket default, LSZH and other premium material availableHigh density and faster cable connectivity

|

2, 4, 6, 8, 12, 24 cores and customized is availableLC, SC, FC, ST connectors with UPC/APC polishing type availableHassle-free installation and erro-free performanceExcellent wooden, plastic and paper spool packaging

|

How to Install and Use the “Pulling Eye”

Pulling eye installation is simple and less tools used. The picture below can illustrate well the installation step. As for the specific situation of assembly, if the assembly is installed inside closed ducting – protection of tails and pulling system may need to be applied. Please consider installation method selecting target design. Some multifibre assemblies features the pulling system applied as a standard whereas for some designs it will be optional.

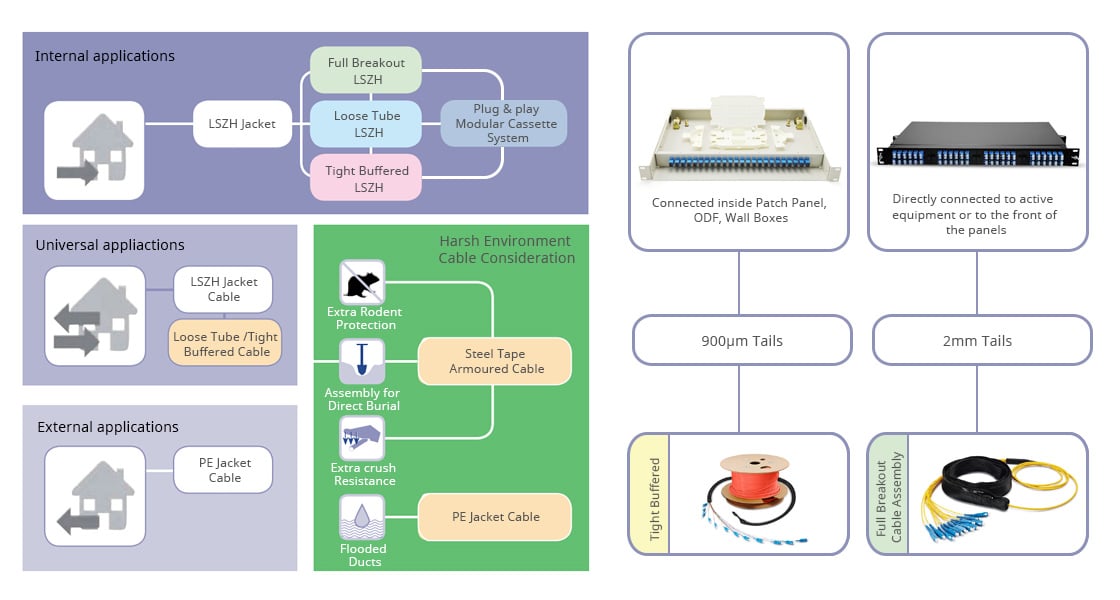

Where Will The Assembly Be Installed And Connected

For different application environment, Fiber-MART provides Internal, External, Universal pre-terminated patch cable types which are of premium characteristics and high performances. The network topology can be reduced and simplified by direct connection to active equipment bypassing wall boxes, ODFs of fiber patch panels, the end result is a greatly improved power budget and reduced fiber management space. For more information, please contact our sales.

Product Guidance